1. Buying and Sellecting the raw material

Source: Mature coconuts (usually 11–13 months old) with thick, white meat and high oil content.

Requirements: No mold, rot, or impurities.

Goal: Ensure consistent input quality – this directly affects the nutritional value and color of the final coconut meal.

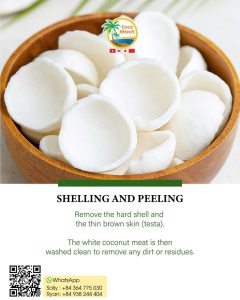

2. Shelling and Peeling

Remove the hard shell and the thin brown skin (testa).

The white coconut meat is then washed clean to remove any dirt or residues.

3. Grinding the Coconut Meat

The white meat is finely ground to prepare for the oil/milk extraction process.

Purpose: Improve oil or milk extraction efficiency and produce a fine, uniform texture for smoother drying.

4. Pressing to Extract Oil or Milk

Depending on the target product (coconut oil or coconut milk), the process varies slightly:

Cold press / mechanical press: Using screw or hydraulic presses to extract oil/milk.

The remaining residue after pressing is called wet coconut meal.

Residual oil content: Around 8–10%, keeping its natural aroma and high nutritional value.

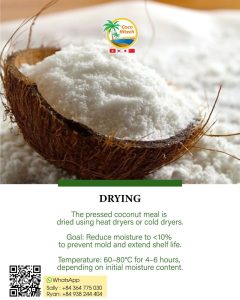

5. Drying

The pressed coconut meal is dried using heat dryers or cold dryers.

Goal: Reduce moisture to <10% to prevent mold and extend shelf life.

Temperature: 60–80°C for 4–6 hours, depending on initial moisture content.

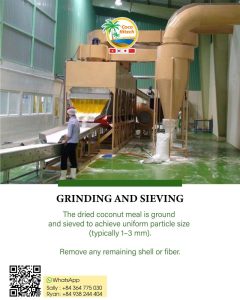

6. Grinding and Sieving

The dried coconut meal is ground and sieved to achieve uniform particle size (typically 1–3 mm).

Remove any remaining shell or fiber.

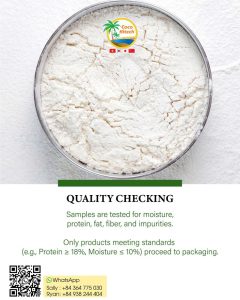

7. Quality Checking

Samples are tested for moisture, protein, fat, fiber, and impurities.

Only products meeting standards (e.g., Protein ≥ 18%, Moisture ≤ 10%) proceed to packaging.

8. Packaging and Storage

Packed in PP bags of 25kg / 50kg / jumbo 500–1000kg as per customer request.

Label includes: “Desiccated Coconut – Product of Vietnam”, batch number, production date, key parameters.

Store in a dry, cool place, away from moisture and insects.

9. Testing and Export

Samples sent to laboratories for COA (Certificate of Analysis).

Containers are loaded, fumigated, weighed, sealed.

Products are shipped through ports such as Cat Lai, Cai Mep, Quy Nhon, or Ben Tre

Amy (English) : +84 965106010 (WhatsApp, Kakao, Line)

Ms. Sally (English) +84 364 775 030 (WhatsApp/Wechat)

대표: Mr. Ryan (Vietnam): +84 938 244 404 (Kakaotalk, Wechat, Whatsapp).

한국어 담당자: +84 364 775 030 | Kakaotalk ID: cocohitech

阮祥薇(中文): +84 397 317 401 ;微信ID:Nttv0608

Been playing at acesupercasino for a bit and gotta say, they’ve got a nice selection of games. Payouts are okay too. Check them out yourself: acesupercasino

That’s a great point about accessibility! It’s awesome when creative tools break down barriers. I recently found Sprunki Retake – web-based music creation is so convenient, no downloads needed! Really inspiring stuff. ✨